Ohio Life

Wooster’s Groovy Cycleworks Offers a Bicycle Built for You

Once you see Rody Walter’s creations, you’ll understand why his waiting list is measured not in months but years.

Related Articles

Rock Salt Vintage Crafts Nature-Inspired Jewelry

Katelin Reeser of Cincinnati shares her love of the natural world through her handmade jewelry pieces that are lasting, durable and unique. READ MORE >>

How Artist Jon Lund Immortalizes Cleveland Landmarks and Icons

His Hudson-based Lund Studio creates a line of beautiful prints that celebrates neighborhoods like Little Italy, natural features such as the Cuyahoga River and more.

READ MORE >>

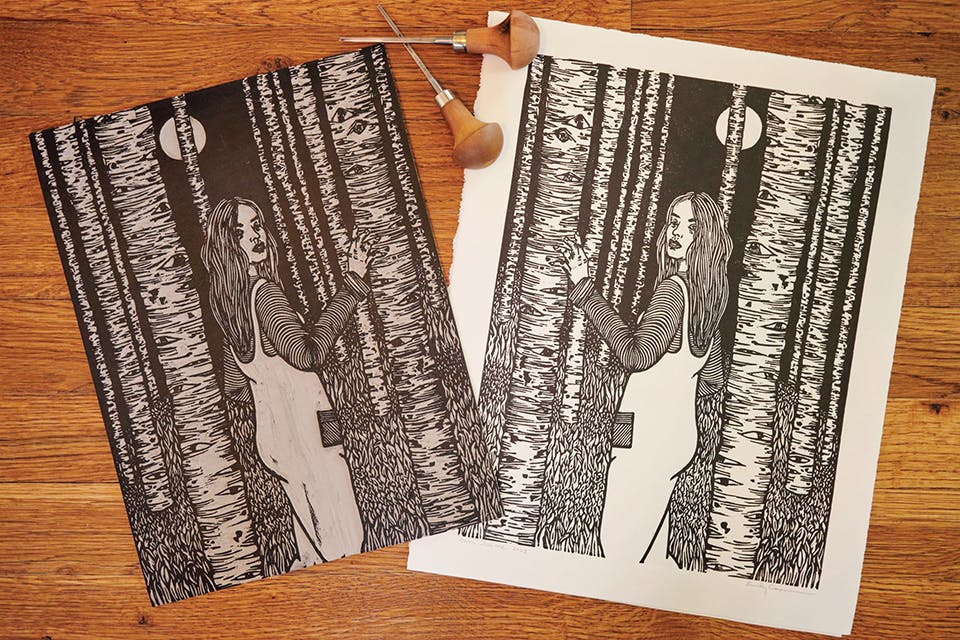

Emily Cooper Creations, Cincinnati

Cincinnati-based relief printmaker Emily Cooper draws inspiration from nature, people and books to craft pieces she hopes evoke a sense of serenity in those who view them. READ MORE >>